In the world of steel construction, precision and speed can make or break a project. Yet, many detailing teams still find themselves bogged down by manual connection modelling, fragmented coordination, and unpredictable fabrication errors.

That’s where SDS2 by ALLPLAN is quietly revolutionizing the execution of structural steel projects—globally and now in India.

As India accelerates infrastructure development, the need for smart, automated & fabrication-ready detailing solutions has never been more critical. SDS2 stands out for its automation-driven workflows, deep fabrication intelligence, and seamless BIM integration. But more importantly, it delivers real-world business impact—faster timelines, reduced costs, and happier clients.

Here’s how this software redefines steel detailing workflows.

Automate More, Model Less: Precision Meets Speed

SDS2 isn't just another detailing tool. It's a time-saving engine built for today's demanding project timelines.

- Faster Project Completion: Over 93% of surveyed users reported significantly faster project turnarounds, with many achieving nearly double the speed.

- Connection Automation: Smart framing conditions trigger automatic connection design—cutting manual modelling by up to 90%.

- Fewer Errors, Less Rework: Built-in clash detection and connection validation help reduce field errors before they happen.

- Tailored Templates: Settings can be customized to match individual fabricator preferences, speeding up onboarding and reducing repetitive tasks.

These features help position SDS2 as a leader in steel detailing and fabrication software for structural engineering and construction professionals.

“SDS2 helped us complete projects on tighter deadlines without compromising quality. It’s like having an extra team member who never sleeps,” shared one user*.

From Model to Machine: Shop Optimization That Pays Off

Fabricators need more than good drawings—they need data that works on the shop floor. SDS2 is built with that reality in mind.

- Material Efficiency: Standardized connection types and plate thicknesses help reduce waste.

- Labor Savings: Smart bolt spacing and optimized detailing reduce fabrication time and labour costs.

- CNC Integration: Direct integration with robotic/CNC machines like Voortman and Peddinghaus eliminates manual data entry.

- high-quality drawing production: SDS2 provides innovative solutions proven to increase profitability and shorten project timelines.

In fact, 86% of users reported improved shop efficiency, and many fabricators in the SDS2 ecosystem have seen project costs drop—without cutting corners.

Joe Sullivan, Structural Detail LLC: “SDS2 sharpens everything you already know and makes you more valuable to your clients.”

Open BIM Interoperability: Collaborate in Real Time, Anywhere

Indian projects are becoming increasingly collaborative, and SDS2 meets this challenge head-on.

- Multiuser Modelling: Real-time collaboration in SDS2 allows multiple team members—even those working remotely—to work on the same model simultaneously. This not only improves efficiency but also keeps everyone on the same page. In fact, 85% of users reported smoother workloads, and 54% successfully enabled remote collaboration—an essential capability in today’s hybrid work environment*.

- Open BIM Compatibility: SDS2 connects effortlessly with over 30 platforms, including Revit, STRUMIS, Tekla, and Sigma NEST.

- Stakeholder Coordination: Engineers, detailers, erectors, and contractors can all access and interact with a single source of truth.

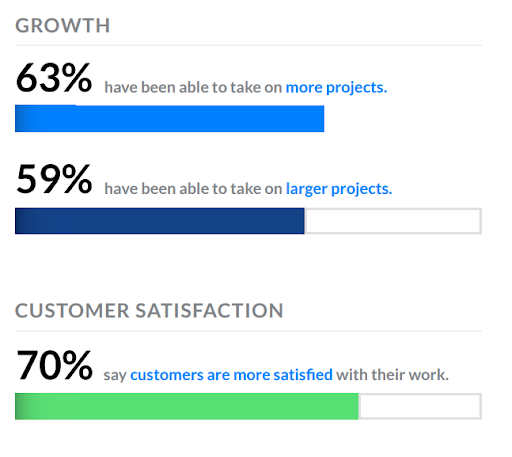

Business Growth, Backed by Data

SDS2 isn’t just a productivity tool—it’s a business accelerator. According to a global study we have received below statical data:

What’s even more compelling? 71% of users saw results in the first year, and nearly one-third reported ROI within 1–3 months.

For teams focused on steel detailing and fabrication, SDS2 helps ensure accurate and streamlined workflows, and projects that stay on schedule and within budget.

Mark Karpinsky, New Jersey Iron: “If I were starting from scratch, SDS2 is the first thing I’d buy, for its role in estimating, detailing, and CNC planning.”

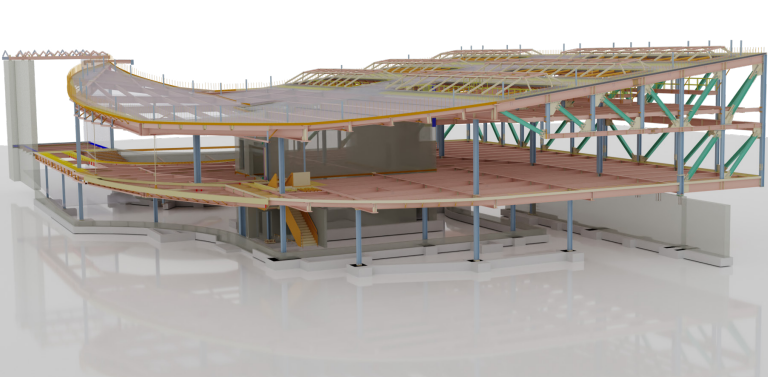

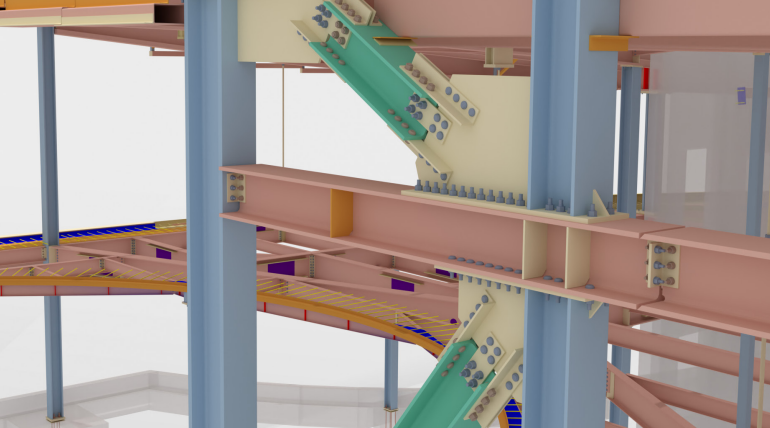

Real-World Projects. Real Results.

From complex urban builds to high-volume industrial plants, SDS2 is already making a difference. Our customers have delivered inspiring projects all over the world, using the power of SDS2’s modeling and automation to save time, minimize costs, and solve problems at every phase in the project, here’s a testimonial from one of the live projects.

Joslyn Art Museum Expansion Project.

“SDS2 was often the leading software for the project teams to understand difficult geometric conditions. Because of the complex geometry, SDS2 was first utilized to come up with connection concepts that were then reviewed by the engineering teams. When architecture and engineering software could not adequately define geometry, SDS2 was used to bring the design intent into focus. ”

DETAILER - KL&A

TONNAGE -1,450

FEATURES

- Rolled, curved staircase

- Curved floor geometry

- Rolling roof geometry

- Cantilevered entrance

For Indian projects with growing complexity, SDS2’s adaptability offers a real edge—whether you’re working with legacy systems or transitioning to full BIM workflows.

More Than Software—A Strategic Partner for India

At Nemetschek India, we believe tools like SDS2 can do more than improve workflows—they can reshape how India builds.

From metros to industrial complexes, SDS2 is empowering India’s construction future. As a leading steel detailing and connection design solution, SDS2 helps structural engineers and fabricators deliver accurate, constructible models that drive efficiency across BIM workflows.

If you're rethinking your steel detailing stack, SDS2 isn’t just another tool—it’s a smarter way to work.

Connect with Nemetschek team at +91 90046 45451

Frequently Asked Questions (FAQs)

What makes SDS2 one of the Best BIM Software Solutions for structural steel detailing?

SDS2 stands out as a Leading BIM software for structural steel detailing software due to its automated connection design, advanced 3D modelling, and real-time collaboration tools. It streamlines fabrication, reduces errors with clash detection, and integrates seamlessly with industry platforms, ensuring accuracy, efficiency, and faster project delivery.

Is SDS2 compatible with other 3D design software and BIM platforms?

SDS2 software offers broad compatibility with leading steel detailing system and BIM platforms. It integrates seamlessly with Revit, Tekla Structures, AutoCAD, and others, supporting data exchange through formats like IFC, DXF, and DWG. This enables efficient collaboration and easy transfer of models between project teams and platforms

Can SDS2 be used by Architectural, engineers and construction in India?

Yes, SDS2 is widely used by both engineers and construction professionals in India. It streamlines steel detailing, fabrication, and erection with advanced 3D modeling, automatic connection design, and collaboration tools. SDS2 improves accuracy, efficiency, and project coordination, making it suitable for the entire construction workflow in India's growing infrastructure sector

For Architectural segment Nemetschek offers solutions like Archicad and Vectorworks, see more details here

How does SDS2 support construction project management?

SDS2 streamlines construction project management through integrated 3D modeling, automated documentation, and real-time collaboration tools. It enhances project coordination with features like clash detection, load planning, status tracking, and direct integration with fabrication and BIM platforms—helping teams reduce errors, optimize workflows, and accelerate schedules for successful project outcomes

Does SDS2 offer tools for mechanical and structural analysis?

Yes, SDS2 offers robust tools for structural connection design and calculation. It enables engineers to generate automated connection, verify member structural integrity, check electability and constructability of steel and has fabrication intelligence within the software or through seamless integration with analysis platforms. While its core strengths focus on structural steel, direct tools for mechanical (MEP) analysis are not included

Is SDS2 suitable for online collaboration and remote teams?

SDS2 is highly suitable for online collaboration and remote teams. Its cloud-based solution supports live multi-user modelling, allowing detailers and engineers worldwide to work on the same model simultaneously. Team members can access, modify, and review projects in real time from any internet-connected device, ensuring seamless remote workflows

Can SDS2 reduce fabrication costs?

SDS2 can significantly reduce fabrication costs. Its automated connection design, clash detection, and cost estimator tools minimize material waste, optimize labour, and improve fabrication accuracy. By streamlining workflows and supporting cost-effective decisions, SDS2 helps projects stay within budget and boosts efficiency for fabricators and detailers