Precision at the Core: How Steel Detailing and Fabrication Are Transforming Indian Construction

07 Jul, 2025 | Nemetschek India Team

Abstract:

India’s construction sector contributes around 9% to GDP and employs over 71 million people but faces delays in over 50% of projects and cost overruns from 20% to 100% (NITI Aayog, 2023). Yet, the sector continues to struggle with real world challenges. In this landscape, steel construction is emerging as a practical, scalable solution faster.

At the heart of its success lies an unsung hero—steel detailing, connecting vision with execution, which has now become an indispensable part of every steel construction project. Ensuring what is designed on paper is precisely fabricated and flawlessly erected. When combined with advanced steel fabrication processes and intelligent software, it allows builders, fabricators, and contractors to reduce errors, save time, and control costs—essentials in a competitive Indian market. This article explores how steel detailing and fabrication are redefining construction efficiency and why they're becoming indispensable to modern project delivery.

Introduction

Construction is an activity to create shelters of human beings since prehistoric age. Since then, it has seen a gradual but consistent change in materials, process, size, complexity. The visible oldest construction evidence starts at 4000 BC which focuses on providing basic necessity of providing a shelter. Earlier construction has been all human labour centric starting from Neolithic age, copper & Bronze Age to Iron Age in terms of using tools for construction. Till the late 1800’s construction was using similar technologies till steel has been used as a material which brought the new era in construction. Over the time construction has developed on factors like durability of the construction materials used, increase in building height and span, the degree of control exercised over the interior environment, and finally, the energy available for the construction process.

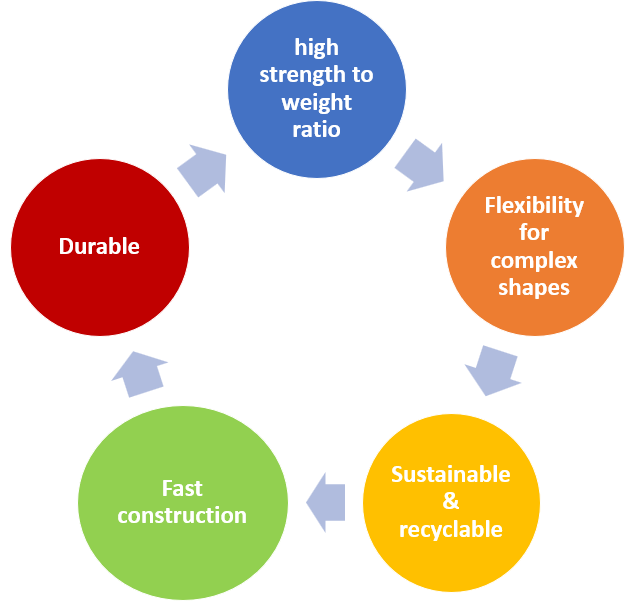

Now in the 21st century, sustainability has also become a very important factor. All the important factors are nowadays considered and designed to reduce wastages and pilferages and optimise for better utilisation of available resources, considering the most critical resource is time. In today’s construction industry, experience new perspectives like environmental impact, health & safety, gender equity, increased confidence on the industry, and an increased appetite for adopting new technologies. Steel has become a preferable choice considering all the above-mentioned aspects. Steel has benefits like reliability, high strength to weight ratio, durability, recyclability, versatility, elasticity, support for longer structures etc. to name a few.

Steel in the Indian Context: A Response to Industry Challenges

The construction industry grapples with numerous challenges, including:

- Rising material costs

- Environmental concerns

- Shortage of skilled labor

- Vulnerability to natural disasters

- Ensuring worker safety

- Inefficient planning processes

- Material shortages and procurement issues

- Project delays and cost overruns and excessive material wastage

- Resistance to change or the "why change?" mindset

- Inaccurate cost estimation and poor inventory management

- Ineffective construction management and scheduling

- Lack of coordination across teams

Steel as a construction material gives unmatched value to tackle some of these problems to deliver projects faster, better and cheaper.

Some of the key benefits of steel can be seen in the diagram below.

Steel Fabrication & the Role of Steel Detailing

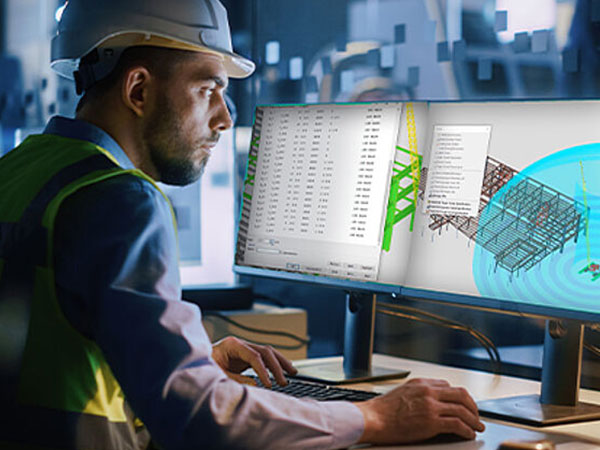

Steel fabrication involves transforming raw steel into pre-engineered components—beams, columns, trusses, staircases—that are delivered to site for assembly. But fabrication is only as accurate as the data that drives it. That data comes from steel detailing.

Steel detailing converts engineering designs into fabrication-ready drawings and CNC data. It ensures:

- Every bolt and plate is accounted for

- Materials are cut precisely as per specifications

- Site teams know exactly how to assemble components

- Fabricators can optimize procurement and avoid wastage

In short, detailing ensures what’s built is what was intended — down to the last nut and bolt.

What Does Steel Detailing Involve?

To design and detail a steel construction projects fabricator has to complete some of the following tasks –

- Design main members & connections

- Create advance bill of material for advance ordering main steel

- Create complete material list for fabrication and procurement

- Create erection plan & schedule

- Use CNC machines for accurate fabrication

- Use manufacturing planning solutions for faster construction

- Coordinate material shipping list as per the construction schedule.

- Coordinate with 3D model at site

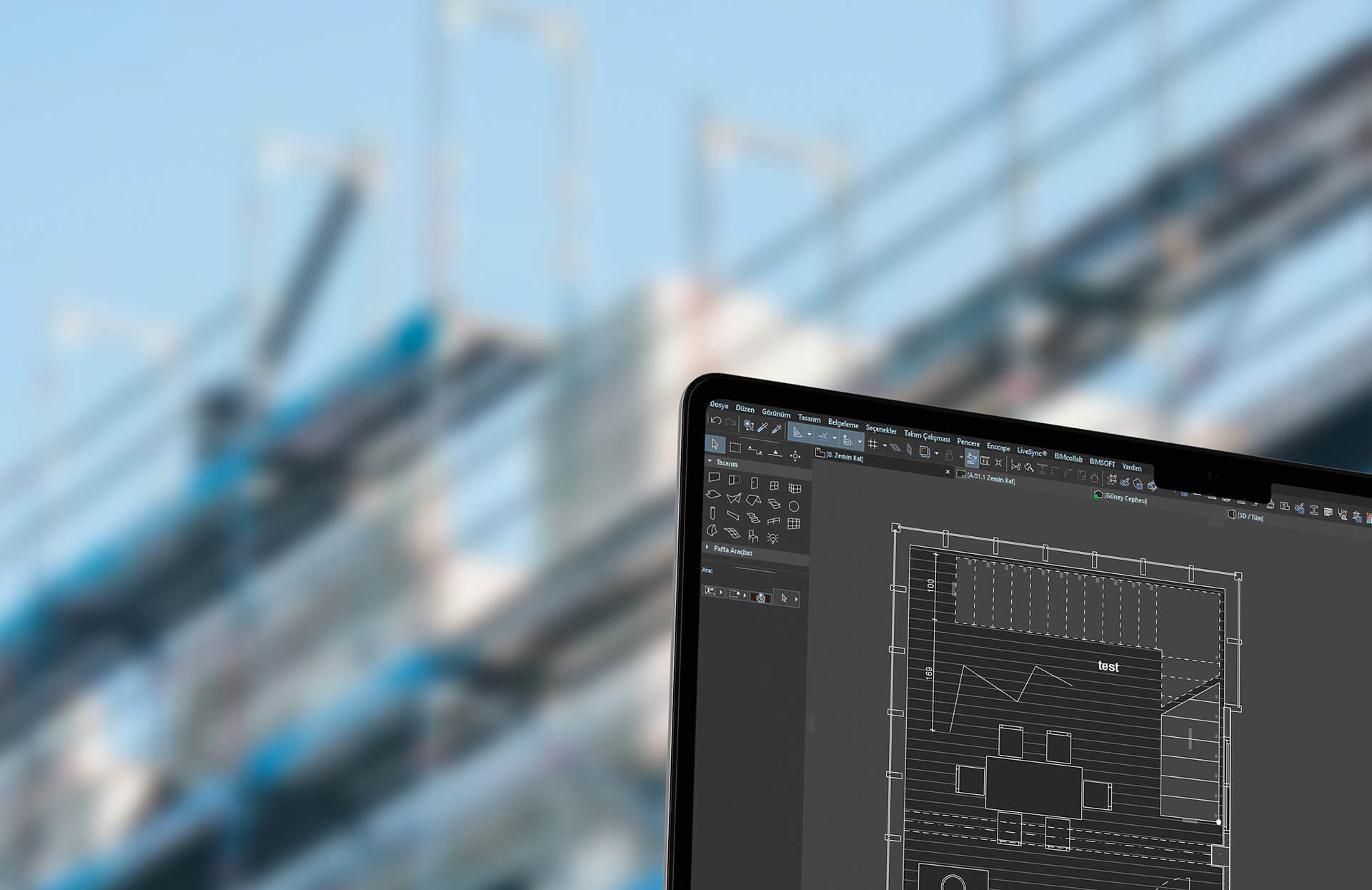

To achieve all the above activities, a fully detailed 3D model is created which works as a heart of the construction projects. While modelling the project accurate detailing, revision management with error checking and advance visualization should be considered.

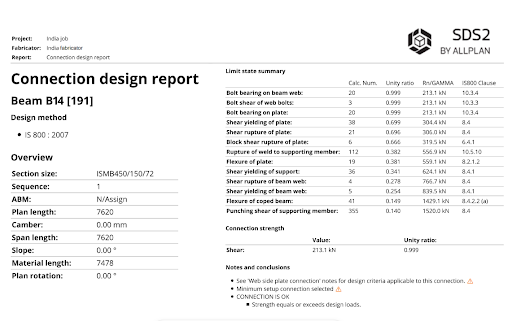

Automated connection design is an activity which not only allows the designer to fast track the design process but also calculation sheets help in fast approval from Engineer on Record (EOR)

Connection Design Report

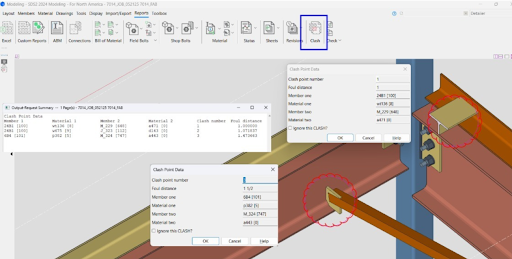

Detecting clashes in the design phase is very critical to remove all conflicts before any steel is fabricated in real. Help’s avoiding any last moment surprises at site and cost and time overruns.

Clash Detection

- Efficiency through Automation - Steel detailing must incorporate advanced automation tailored to each fabricator’s internal workflows, while remaining flexible enough to adapt to a wide range of fabrication processes.

- Streamlined processes: Automated design, detailing, and reporting eliminate repetitive tasks, allowing teams to focus on higher-value activities.

- Seamless integration: The software integrates with other tools used in the construction process, such as Building Information Modelling (BIM) platforms, ensuring smooth data transfer.

- Faster project delivery: By automating key stages of the design process, SDS2 enables quicker project completion without compromising quality.

- Accurate Shop Drawings & reports – Steel detailing software generates detailed shop drawings, providing fabricators with precise instructions for cutting, welding, and assembling steel components. It also gives detailed bill of material, CNC data for fabrication and MIS reports for production management.

- Improved fabrication: High-quality drawings minimize fabrication errors.

- Consistent standards: The software ensures all drawings meet industry and project-specific standards.

- Cost & time saving - Cost is the crux of any steel detailing software and these can be achieved by below factors –

- Reduced material waste: Accurate detailing minimizes errors and optimizes material usage.

- Lower labour costs: Automation reduces the need for manual labour, saving time and money.

- Fewer project delays: By preventing errors and streamlining processes, SDS2 ensures projects stay on schedule.

- Enhanced Collaboration and Communication - Collaboration is critical in structural steel projects, where multiple teams—engineers, architects, fabricators, and contractors—must work in sync. SDS2 facilitates this collaboration with its user-friendly interface and data-sharing capabilities.

- Centralized information: The software provides a single source of truth, ensuring all stakeholders have access to up-to-date information.

- Efficient communication: 3D models and detailed drawings make it easier to convey design intent, reducing misunderstandings.

- Remote accessibility: Cloud-based functionality allows teams to access project data from anywhere, enabling effective collaboration across locations.

Gillette Stadium North End-Zone Renovation (U.S. Benchmark, Indian Relevance)

This renovation project revitalized the iconic home of the New England Patriots football team. It featured an enhanced 218-foot lighthouse, a 22,000-square-foot high-def video board, and additional amenities. The project came in at 3,000 tons, and structural challenges were numerous with multiple types of truss framing connections at cruciform columns, heavy connections at vertical and horizontal brace locations, and coordination of precast elements on sloped beams and columns.

Reinforcing India's Growth with Digital Detailing

India’s construction ambitions are sky-high—but execution on the ground often falls short due to planning and coordination gaps. Steel detailing, paired with advanced fabrication methods, offers a proven way to bridge this gap.

It minimizes waste, maximizes clarity, speeds up delivery, and—most importantly—brings certainty to an otherwise unpredictable process.

As India builds faster, higher, and smarter, it’s time to bring steel detailing out of the background and place it where it belongs: at the core of construction excellence.

Contributed by

Mitra Barun Dutta

GM – Sales (Execution)

Book a Demo See It. Believe It. Call us @ 90046 45451

*Sources

- Manufacturing, construction & most services will drag FY25 GDP growth to 6.4%, govt estimate predicts

- https://www.news18.com/india/india-third-largest-construction-market-2025-infra-boom-8788759.html

- https://www.business-standard.com/economy/analysis/cost-overruns-ebb-yet-delays-persist-in-half-of-major-infra-projects-123083100035_1.html

- https://www.mckinsey.com/capabilities/operations/our-insights/reinventing-construction-through-a-productivity-revolution