Smarter Steel, Faster Builds: The SDS2 Advantage for Future-Ready India

25 Aug, 2025 | Nemetschek India Team

India’s construction industry is undoubtedly growing, driven by government initiatives, rising urbanisation, and increasing demand for housing and industrial infrastructure

With this there is undoubtedly rise in complex infrastructure needs, tight timelines, and razor-thin margins. Delivering faster, safer and cost-effective projects are no longer an option, Steel fabricators and structural detailers are under constant pressure and all while grappling with rising material costs, skill shortages, and increasingly intricate project demands.

Yet, our reliance on disconnected tools and outdated workflows is heavy.

Coordination gaps, manual modeling, inefficient data exchange, and last-minute shop-floor rework can derail even the most carefully planned projects.

The result? An inefficient workflow, time lapse, delays, cost implications and frustrated teams

This is where intelligent, integrated detailing solutions become not just useful—but essential. And SDS2 Software by ALLPLAN is leading that charge.

Its deep integration with Tekla PowerFab is another innovation enabling detailers and fabricators - a powerful sync that connects design intelligence with fabrication execution. Not just streamline workflows but it redefines efficiency across the entire construction lifecycle.

The Challenge: Outdated Workflows in a Fast-Moving Industry

Detailing and fabrication workflows often operate in silos. To top it off connection designs are done manually, coordination with engineers and contractors happens through email or paper markups, and CNC outputs require additional manual steps.

Resulting in

- Inaccurate Bill of material (BOMs) and drawings, leading to wasted materials

- Last-minute clashes during erection or fabrication

- Time-consuming rework, increasing cost and delaying schedules

- Difficulty in traceability, making it hard to track errors or optimize future jobs

In an industry where margins can be thin, these inefficiencies add up quickly.

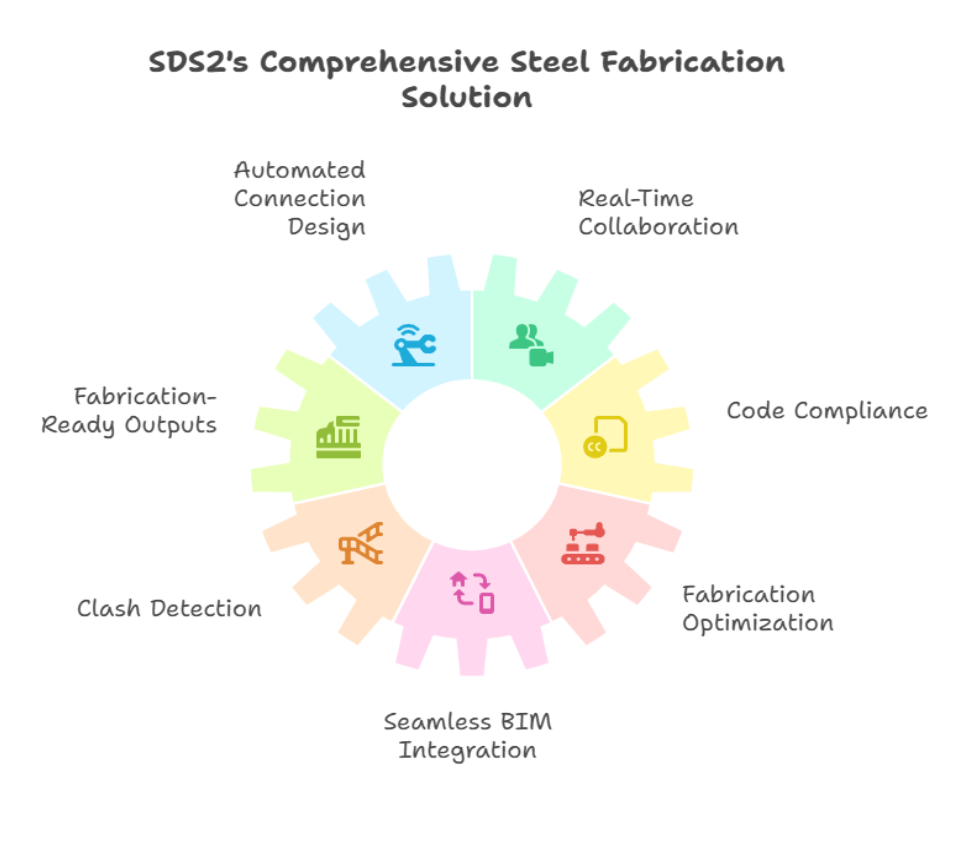

SDS2: Intelligent Steel Detailing

SDS2 is not just a detailing software tool — it brings together connection design, automation, collaboration, high quality production drawings and fabrication-ready outputs all under one roof. Now available in India through Nemetschek, SDS2 software contains IS800 codes and transforms how projects are detailed, fabricated, and delivered.

Here’s Why SDS2:

Automated Connection Design That Saves Time and Reduces Errors

SDS2’s biggest strength lies in its intelligent connection design engine. Instead of manually modeling connections for every joint, SDS2 evaluates framing conditions and automatically generates structurally sound, code-compliant connections. Whether you’re working with Indian codes, AISC, CISC, Euro, or British standards, SDS2 adapts and delivers.

This automation can reduce manual modeling time by up to 90%, freeing up valuable hours and dramatically reducing errors.

Real-Time Collaboration for Distributed Teams

With SDS2, multiple users can edit the same model simultaneously, allowing real-time coordination between detailers, engineers, erectors, and fabricators — even across continents. Features like Connection Cubes enhance communication by providing 3D visual reports that clarify connection intent, reducing back-and-forth between design and fabrication.

Cloud licensing and usage analytics provide flexibility in access and resource planning, ideal for growing teams.

Fabrication-Ready Outputs with Seamless CNC Integration

SDS2 bridges the detailing-fabrication divide by exporting DSTV/DXF files directly to CNC machines, cutting out intermediate steps and minimizing human error. Shop and field drawings are automatically generated with accurate bolt patterns, weld information, and member specifications.

Templates can also be customized to match individual shop capabilities — optimizing material use and reducing waste by up to 30%.

Seamless BIM Workflows and open BIM Compatibility

SDS2 exports all market popular file types like xml, IFC 4 & IFC2x3 and integrates with key platforms like Automated machines, Bimplus, STRUMIS, and Tekla Powerfab, ensuring smooth handoffs and consistent data across the project lifecycle.

But perhaps the most impactful integration is with Tekla PowerFab.

The SDS2 + Tekla PowerFab Advantage: A Closed-Loop Workflow

The integration between SDS2 and Tekla PowerFab enables a data sync. Using a dedicated plugin, SDS2 exports geometry, BOM, CNC data, and production files directly into PowerFab.

- Fabricators are leveraging the sync by eliminating duplicate data entry enabling them to complete job setups faster by 63%.

- GUID-based tracking ensuring traceability from model to shop to site.

- 30% reduction in rework through clash-free designs and real-time updates

- BOM data supersedes model data in Tekla PowerFab, eliminating discrepancies.

Important links for a deeper understanding

- Tekla PowerFab toolbox plugin for a deeper understanding.

- Watch the integration in action here

- Don't Believe the Rumors. Here's How to Sync SDS2 and Tekla PowerFab

- How to Efficiently Export PowerFab from SDS2

- SDS2 and Tekla PowerFab Data Transfer Best Practices

SDS2 latest innovations

The 2025 release of SDS2 continues to push boundaries for precision.

- Enhanced welding visualization with customizable shop/field colors and weld polygon displays.

- Improved connection logic for tube columns and punching shear checks

- Automated fabrication intelligence which enables notch and cope for clash free model.

These updates, while technical, directly translate to faster shop drawing approvals, fewer surprises in the field, and a more consistent QA/QC process.

SDS2 enabling Indian infrastructure

Across bridge projects, stadiums, and industrial builds, SDS2 has demonstrated its ability to compress timelines by 40%, reduce manual calculation work by 75%, and eliminate paper-based workflows through integrations with platforms like Bluebeam.

Providing a clear strategic advantage to Indian fabricators who are competing for global projects

Why SDS2 Wins

SDS2 doesn’t just digitize your current workflow — it reimagines it. By uniting smart automation with deep integration, it empowers teams to work faster, smarter, and with fewer errors.

93% faster project completion | 86% shop efficiency gains | 100% paperless workflows

In today’s construction economy, where every hour and kilogram of steel counts, SDS2 is the engine that powers next-gen steel fabrication detailing tool.

Connect with Nemetschek team